| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

kg

TOTAL COST

$1660| Model : HJ-01 | Payment Terms : L/C, T/T, Western Union, Other | Delivery Port : Guangzhou-Huangpu | delivery Time : 3-10 | Product Advantages : Well and High Quality Control, Prompt Delivery, Competitive Prices, Earth-friendly Products, ODM Accepted, Other |

| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

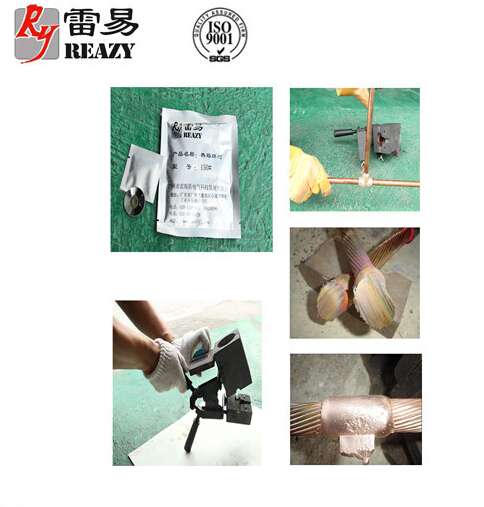

Molecular joint thermite exothermic welding powder for metal connection

Product Description

Exothermic Welding powder is also known as exothermic bonding, thermite welding (TW), and Thermit welding. There are many advantages of using Exothermic Welding powder. The most important one being that the process produces a molecular joint and not just a mechanical one in between the conductors. It is produced through a starting reactant which provides enough energy to activate the welding reaction. This takes place quickly and safely inside a graphite mould. The mould is designed specifically for a certain union depending on the elements to be welded and the joint type required. We guarantees all types of joints, not only copper cable unions but also to weld tapes, brass metallic pieces, stainless steel, steel ground rods covered with copper, etc. It is especially useful for joining dissimilar metals.

Feature:

1.It has a superior electrical conductivity than the conductors themselves.

2.It does not corrode oxide or degrade with time and is resistant to galvanic coupling.

3.It is able to withstand repeated electrical discharges.

4.It never increases its resistance.

5.It has higher mechanical and squeezing resistance than the conductors themselves.

6.It offers a permanent welding and a low resistance connection, essential for achieving longwearing and trustworthy results in earthings

7.It guarantees the most common connections not only between copper cables but also for welding tapes and metallic pieces made of brass, stainless steel, and copper coated steel earth rods.

8.portability, lower cost (because they can be reused), and flexibility, especially in field applications,requires no external source of heat or current.

Pcking and specifications:

Note: Per bag welding powder with one bag ignition starting powder(2-4g) and metal disk in free.

Application:

Grounding and surge protection.

Electrical equipment grounding engineering processing.

The petrochemical engineering construction.

Photovoltaic (pv), railway, highway and airport construction.

Intelligent building construction.

The cathode anticorrosive protection.

Opertion program

Field construction :

Exothermic Weld Accessories

1) Graphite Mould

Graphite mould is made of high quality graphite suitable for high quality welding work and can be used for several times.

Following are the advantages.

1. A smooth metal connection that will not loosen or corrode.

2. It is not affected by high current surge or over current.

3. No need for the external welding machine.

4. Use only lightweight and cheap equipment.

When making a copper wire connection of Ground rod or other metal connection, place the weld powder intothe graphite mould. Just ignite to start the welding process. The result will be clean and smooth connection surface. It is also applicable for other metal such as: Iron, Galvanized

Steel, Railway track, Cast Iron, Bronze, and Brass. It can be used in various applications to have the certainly good connections in work. Such as Lightning and Surge Protection, Grounding in Electrical Work, Railway Construction, Cathodic Protection. The connection mould is designed to

last for an average of 100 to 130 connections. This will vary according to the care given the mould during use.

2) Mould Handle Clamp (Universal)

For most connections involving lugs, cable or rectangular bus, exothermic handle clamps are used.These will fit 90% of all standardexothermic molds. Normally we recommend one Handle for everytwo moulds

3) Steel Metal Disk

Steel discs are very important. The disc acts timing device to allow the welding powder to heat to proper temperature, the disc away allowing the molten copper to a point where it would weld metal toenter the weld gravity before ignition. One Metal is must for every shot

4) Exothermic Weld Powder

Exothermic Weld Powder is the most reliable and consistently-performing weld metal available

with us. Quality validation steps are taken for every lot we produce. Upon final acceptance,

our weld metal is specially packaged in moisture-resistant plastic cartridges with special closure caps. Then the cartridges and required metal discs are packaged in moisture-resistant boxes.

All sizes of weld metal are available.

Standards Size Packing available are – 50 Grams, 100 Grams, 125 Grams

150 Grams, 200 Grams, 250 Grams, 1 Kilogram

Anti-Moisture Free Packing in Foil

5) Ignite Powder (Starting Powder)

Ignite Powder also known as Starting Powder is required and is must. Pour little Starting Powder on the Mould followed by the Exothermic Weld powder and again pour it little on the Top Side of Mould. Ignite starting powder with a spark gun.This resulting exothermic reaction reduces the

weld powder to molten copper alloy. The molten copper alloy melts the retaining disc and flows

into the weld cavity where it partially melts the conductors. Ignite Powder of 5 grams is sufficient for this Process.Ignite Powder

6) Flint Gun

It is designed with the advantages of safety and convenience. It is used to ignite Starting

Powder in order to result in exothermic reaction.

We recommend one Flint Gun for every 100 Shots

7) Gloves

Gloves is required for safety purpose as the Exothermic Weld Powder melts at more than

1400 degree Celcius.

8) Brush (Soft and Hard)

Two Brush Required:

1) Soft Brush – Its used to Clean Mould Weld Cavity because its shape is very sensitive

and there should not be any damage while using Brush, so we recommend to use Soft

Brush to Clean Mould Weld Cavity

2) Hard Brush – Its used to clean other section of Mould

We recommend a Pair of Brush for 50 Connection

Brush to clean Mould

9) Slag Removal Tool

It is used to remove the metal Scrap from Mould

Slag Removal Tool

11) Sealing Compound

Sealing Compound is used to fill the gap on the mould if any.

Sealing Compound

Welding tool box

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.