| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Model : JF-A390 | Payment Terms : L/C, T/T, Western Union | Delivery Port : Qingdao | delivery Time : 15days | Product Advantages : Well and High Quality Control, Prompt Delivery, New Product, Competitive Prices, In a Variety of Design, ODM Accepted, OEM Accepted |

| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

Product Description

The A Type Layer Battery System is designed both open and close house all over the world,especially for open house in big farm who has enough land,it is more suitable to be used in tropical zone such as Africa,Southeast Asia and South Asia Countries.

|

New Design Poultry Layer Cages With Feed System For Chicken |

|||

|

Chicken Cage |

Size |

L195cm*W35cm*H38cm,3Pcs/cell,2/3/4/5 tiers by clients’ option |

|

|

Material |

Q235 steel ware |

||

|

Surface Treatment |

Hot dip galvanizing |

||

|

Capacity |

90--200chicken one set |

||

|

Accessories |

Nipple Drinker |

Stainless steel nipple drinker,warranty>8years |

|

|

White Pvc Feed Trough |

Made of concentrate PVC |

||

|

Water Pipe |

Made of PVC |

||

|

Cage Frame |

U type steel,angle iron or galvanized plate |

||

|

Automatic System |

Automatic Feeding System |

||

|

Automatic Manure Removal System |

|||

|

Automatic Egg-collection System |

|||

|

Automatic Temperature Controlling System |

|||

|

Payment Terms |

Deposit is 30% T/T in advance,and the balance paid before shipment,for EXW. |

||

|

Packing Details |

Packing according to the export equipment package standard. |

||

|

MOQ |

40 set chicken cage |

||

|

Leading Time |

30 working days upon your deposit. |

||

Detailed Images

A Frame System Layer Battery System

The A Frame System Layer Battery System from Henan Jinfeng is Cold Galvanized or all Hot Dipped Galvanized Equipment,we can control the standard and quality because Jinfeng has our own Wire Drawing Production Line to produce the cage wires, Automatic Cage Mesh Welding,Cutting,Bending and Cold/Hot Dipped Galvanization for Cages and Cage Leg Frames.

1.Saving more cost for Farmers because its much lower investment as H Frame Cage System;

2.More Suitable to use in rainless district,durable and solid structure for long lifetime;

3.Greater number of birds is reared per unit of area and it helps in identifying poor producers

and prompt cullings;

4.Easily to deliver and installation in clients farm and make maintenance;

1.Nipple Drinker:Stainless steel nipple drinker,Warranty>8years.

2.White Pvc Feed Trough:Made of concentrate PVC,Length is 4m/Pcs,Loading capacity>60Kg/PC.

3.Water Pipe :Made of PVC,4m/pcs,Special poultry water pipe.

4.Cage Frame:U type steel,angle iron or galvanized plate,Galvanization surface treatment,Warranty>10years.

5.Water pressure controlling system:Supply average water to the pipe.

6.Egg controlling belt:Made in Italy,Width=100mm.

We obtain the patents and named the machine by our factory name,but the OEM Design is available! The Machine collects eggs from various tiers of the cage.All the eggs are collected in the front platform for packing or collected on the cross conveyor system to transfer the eggs to packing machine or egg store house.

Automatic Feeding System

Name:A type feed machine

1)Saving more labors because the automatic control panels can control feeding trolley

2)It makes the A and H frame cage system being higher as 3--8 tiers

3)The board are made of Aluminum Zinc plate,antirust and strong structure

4)Very easy to make installation and connect with the silo,feed delivery are automatic

Name:Silo

3.4Ton:Height 3.93m;Volume 5.06㎥; Hot galvanization ≥275g/m2;

4.2Ton:Height 4.41m;Volume 6.32㎥;Hot galvanization ≥275g/m2;

5.4Ton:Height 5.05m;Volume 8.01㎥ Hot galvanization ≥275g/m2;

6.2Ton:Height 5.53m;Volume 9.27㎥;Hot galvanization ≥275g/m2;

1.Special design for A frame Cage System with manure pits under the cages,the various width of manure scraper are available.

2.Lower cost and easily to operate by control panels.

3.Easily to install and make maintenance during the use.

4.Solid structure and durable because of hot dipped galvanized manure scrapers and imported Nylon connection hemp ropes.

5.This system can be used in different A frame cage systems as layer,pullet,broiler and breeding chickens in close or open house.

6.Cleaning the chicken house inside immediately in order to control the ammonia emission.

Name:Ventilation Fan

1.Six stainless steel blades are self cleaned,with a stamping process by computer mathematical model.

2. V-belt from MITSUBOSHI,with high strength,long life span and little maintenance.

3.100% copper cored motor from Chinese famous brand;Protection grade-IP55;Insulation grade-F

4.Nylon centrifugal opening device pushes louver leaves quickly and flexibly,then ideal temperature and ventilation effect can be realized.

Name:Cooling pad

1.Made of high-quality cellulose paper,with 45°angles and clean cutting edges,not leading to dust collection surface.

2. Great permeability ensures water is uniformly

distributed along the length of the pad,contributing to higher cooling efficiency.

3.Containing no surface active agent.Cooling pad absorbs water quickly,with high diffusion rate.Awater drop can be totally diffused within 4-5 seconds.

4. Water absorption can reach up to 60-70mm/min or

200mm/1.5 hour.

Intelligent EC system is one automated system especially used in standard poultry shed. It is designed according to standard poultry farm. It can be set to control lateral exhaust fans, longitudinal exhaust fans, cooling pads, pumps and so on. Based on this function, it can automatically realize discharging NH4, heating and insulating, lowering temperature and alarming and so on. Such system can run without labor on duty. It is simple to operate and run stably. Requirements for big scale farms can be satisfied well by such system.

Wire Drawing——Welded——Galvanization——Drying

Packing & Delivery

Packing:All the Component of the cage will be in partial packing,and then you can install them easily.

We also can pack according to your requests.

Delivery:30 working days upon your deposit.

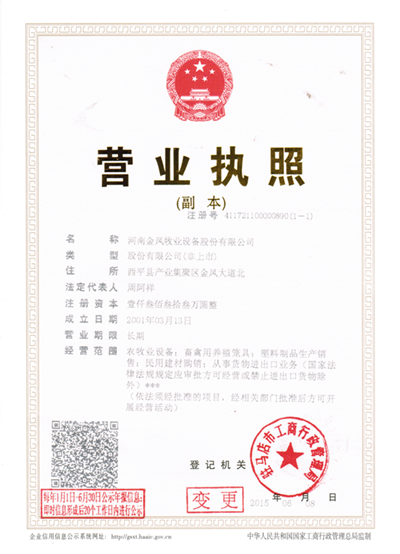

Our Company & Team

Our Company

Certifications

Our Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ

1. Q : What is the advantage of your products and services?

A:

1. we have more than 20 years of production experience , meanwhile our products have been improved

2. we have the professional designers help you design the chicken house and provide you with free chicken house construction drawing paper

3. we have the professional knowledge of breeding ,we can give you more advice

4. Our products have passed ISO 9001 quality Certification, our quality more secure

5. Our high quality product’s service life is more than 20 years

6. We can guarantee 5 years quality about the plastic accessories, we can free replace it for you if there are any quality questions within 5 years

2.Q: what’s your payment?

A: we have 3 kinds payment

1. Accept payment of TT 30% in advance and 70% after you receive the copy of BL

2. We can accept L/C if the orders amount more than 500,00

3. Alibaba credit guarantee payment

3.Q: what’s the minimum order quantity ? How many sets chicken cage for 20 feet container and 40HQ container?

A: Our MOQ is 40 sets, one 20 feet container can loading 100-150 sets, one 40HQ container can loading 240-320 sets.

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.