| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Model : RA-800 | Payment Terms : L/C, T/T, Western Union | Delivery Port : shanghai | delivery Time : 5-15days | Product Advantages : Well and High Quality Control, Prompt Delivery, New Product, Customer‘s Design and Logo are Welcome, Competitive Prices, Fit for Gifts and Premiums, Earth-friendly Products, In a Variety of Design, Small Order Acceptable, OEM Accepted, Other |

| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

Product Description

Intraduction:

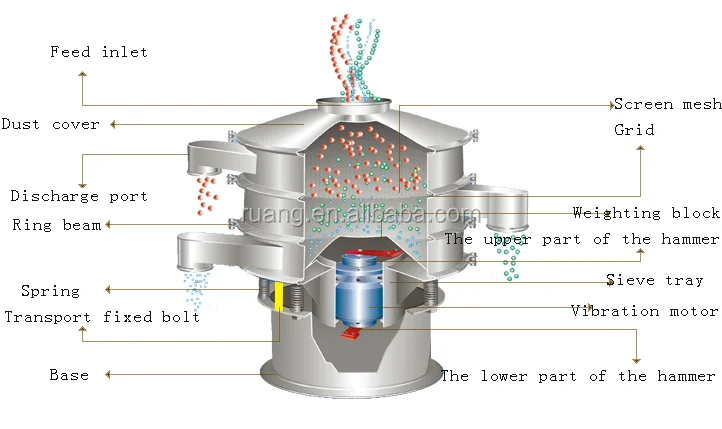

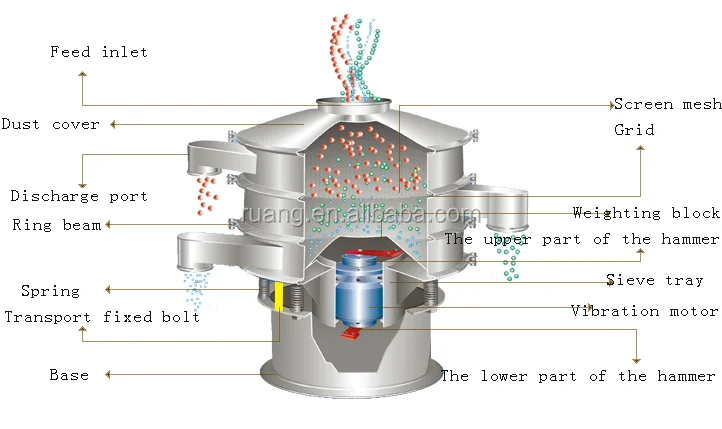

The uitrasonic vibration sieving system is composed of the ultrasonic resonant powder supply oscillator and resonant ring. The high frequency electric oscillation produced by the ultrasonic reasonant powder supply is transformed into high frequency 3D oscillation wave is then transferred to the reasonant ring which then transfers the vibration evenly into the mesh surface. The ultrasonic vibration together with the 3D low frequency vibration prevents mesh blocking and meanwhile improves the sieving output and quality.

1. Grade: SUS201,SUS304,SUS316

2. Voltage:220v,380v

3. Screen Mesh:Stainless steel

4. Certification: ISO9000

|

product Name |

Ultrasonic oscillating vibrating screen swinging sieve screening equipment |

|

Material |

Contact parts with the material of stainless steel |

|

Vibration Frequency |

36.5KHZ |

|

Cleaning system |

Ultrasonic device |

|

Feeding Granularity |

500mesh or 0.028mm |

|

Weight |

200kg |

|

Model |

RA- |

|

Advantage |

Special for ultrafine powder |

Products Show

Exhibition visitors

Our Company

Our factory

Our office building

Ultrasonic system research cooperation base

Packing & Delivery

Packing Details : Our ultrasonic vibration sieves are packed in plywood case or as your requirment

Delivery Details : within 5-10 working days after receipt of your payment

Product releated

Product details

The features of ultrasonic vibrating sieve:

1. Better sieving results are reached by combining mechanical and ultrasonic vibrations.

2. Higher throughputs and good screening efficiency, even for screening materials which are difficult to be screened.

3. Raise screening precision, also the output can be raised several times.

4. Stainless steel screen mesh that guarantees a longer screen service life.

5. Be suitable for sieving the ultra-fine powder, especially for the materials difficult to process.

6. In achieving high precision and high mesh screening at the same time.

Function: efficiently sieving power with features of light density, low humidity, easy adhesion or super fine powder. It can completely solve the difficult screening problems that similar screening machines cannot solve.

1.The product has the self-cleaning function:the mesh cannot be blocked up

2.Does not change the characteristics of screening materials

3.All material contact parts are stainless-steel 304

4.The granularity may be raised by 1-70%,and the output may be improved to 10 times at most

5.Strong absorbability,easy to reunite,high static electronic,high density,light proportion and so on

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.